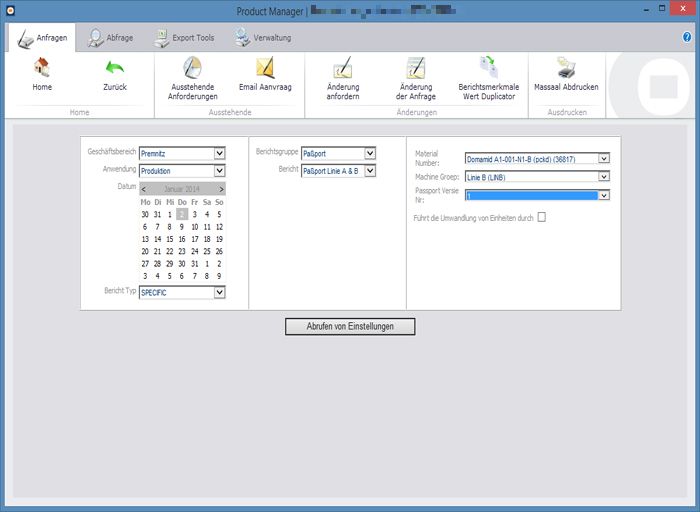

Apart from planning and stock registration, there is an extra module available to the production department so as to allow for a follow-up of the production-specific parameters and settings. Most of the time, this follow-up is realized by means of Excel files and made available in paper format, and is inadequately updated. By storing this within a database, these data will be immediately available within the other Orbitus applications. Our Product Manager is unique for its design. In order to make it usable in diverse sectors, the production-specific features (temperatures, weights, …) are dynamic, which means that we configure them and no programming is required, if some extra features are to be added. But also the references (references to which the features are applicable, such as material, combination of material/machine) are of a dynamic nature. This way, the operator can use it in any way he wants.

Features

- The basis of the Product Manager are the configurable features. All the necessary parameters that need to be kept up-to-date, are defined. Grouping and linking per area and application is possible.

- In addition to the configurable features, the references (to which the features are linked) are of a dynamic nature. This way, a particular feature (e.g. temperature) may be given a certain value for a product, that may differ if the same product is manufactured on another machine. This is a powerful mechanism and thus we can avoid needless redundancy.

- Automatic conversion between units. This is convenient and necessary when the manufacturing is realized in various countries. For example the metric system vs the British or American system. This possibility was elaborated because also commercial datasheets were drawn up by the product manager. Here it should be possible to supply the data in the British system as well. The data are stored in one unit, the conversion into other units may be applied at any time.

- Multiple languages are supported

- Also a convenient workflow is present in order to request value adjustments. These are then submitted for approval by the manager by means of the workflow. A full history of all modifications is kept up-to-date. This way, it can be viewed at any time what was requested and adjusted by whom and when. This is a major surplus value in terms of tracing.

- A simple Excel upload / download is available in order to allow for easy and fast management of large quantities of data. This way, the necessary data can be duplicated, adjusted and uploaded in a simple and familiar way. This makes it easier to join in and use the Product Manager with faster results.

- The Product Manager is integrated with the other Orbitus applications so that the data can be promptly retrieved within the other applications.

Why Orbitus?

- Unique & efficient graphical planning board – crystal clear and simple

- Full integration between planning, shop-floor and warehouse – data integration at its best.

- MES & WMS within the same database for maximum return and traceability – all data immediately accessible

- Real-time return measuring and reporting by means of direct machine link for automatic data capturing – correct and independent data with little effort

- High-level integration with ERP – close interfacing with SAP

- More than 10 years of experience within diverse industrial environments